User blogs

Tag Search

Tag search results for: "video borescope"

ViewTech Borescopes Showcasing VJ-3 Video Borescope Inspection Technology

TRAVERSE City, Mich., April 22, 2022 (SEND2PRESS NEWSWIRE) — Having previously exhibited at CastExpo, ViewTech Borescopes will be returning to the triennial American Foundry Society event and demonstrating their remote visual inspection (RVI), nondestructive testing (NDT) technology at booth #509. Thousands of foundry professionals will convene at the Greater Columbus Convention Center in Columbus, Ohio from April 23 through 26 to network, sit in on technical sessions, and learn about the latest metalcasting equipment.To get more news about [url=https://seesemborescopes.com/]industrial videoscope[/url], you can visit seesemborescopes.com official website.

Sales Consultant, Chris Courtright, will be on hand during exhibit hours and displaying several ViewTech borescopes, including a VJ-3 Dual Camera, VJ-3 3.9mm, VJ-3 2.8mm, and VJ-3 2.2mm. “Our line of video borescopes assists professionals conducting inspections, maintenance, and quality control procedures,” stated Courtright. “The VJ-3 Dual Camera video borescope was not available the last time we exhibited at CastExpo and is one of our most favored borescopes for sale, especially among those completing casting industry inspections.”

ViewTech Borescopes invites both CastExpo attendees and exhibitors to visit booth #509 and experience a VJ-3 video borescope. ViewTech’s no-cost, no-obligation demo program will ship you a full-featured articulating video borescope to trial at your own facility. ViewTech will be in the company of nearly 300 additional exhibitors, including ASK Chemicals, Cortec Corporation, Equipment Manufacturers International, and Sinto America.

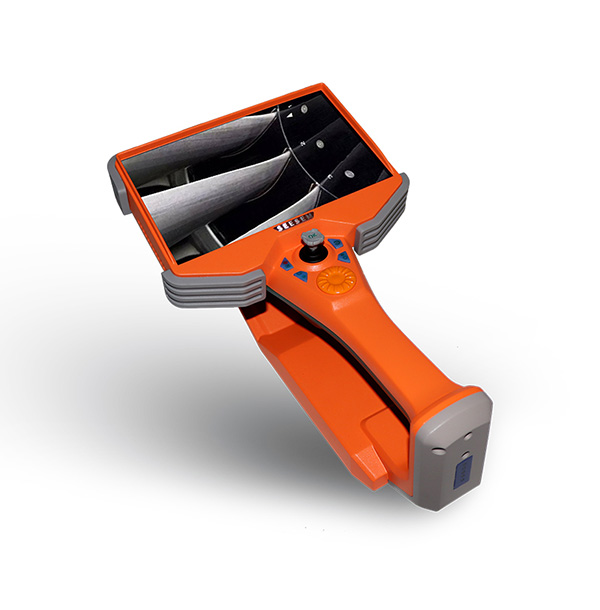

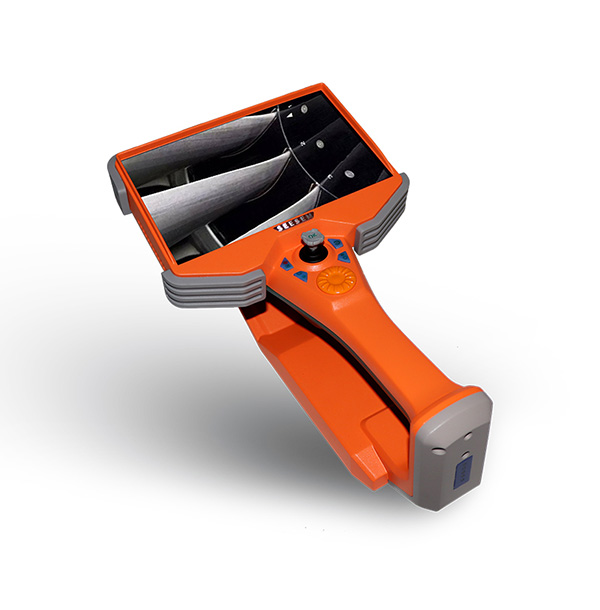

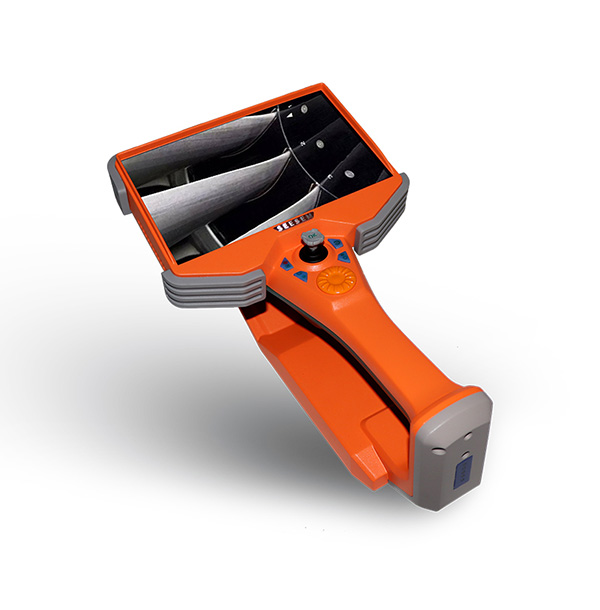

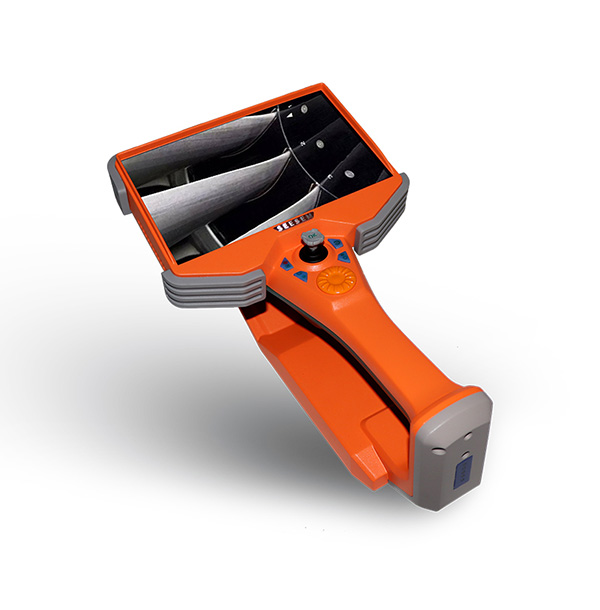

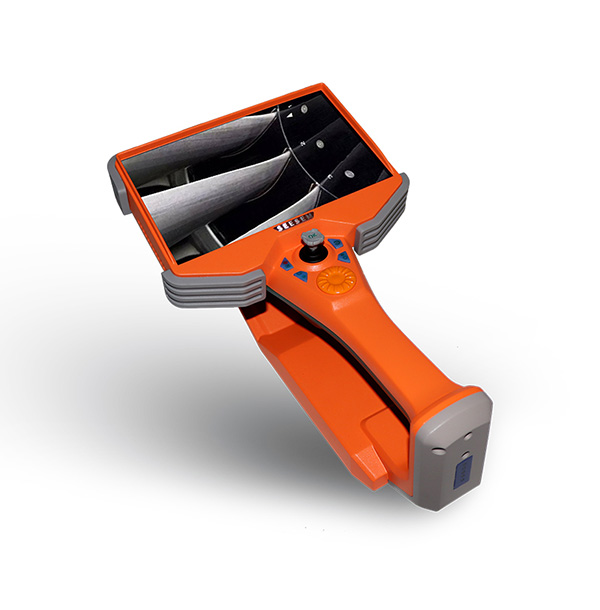

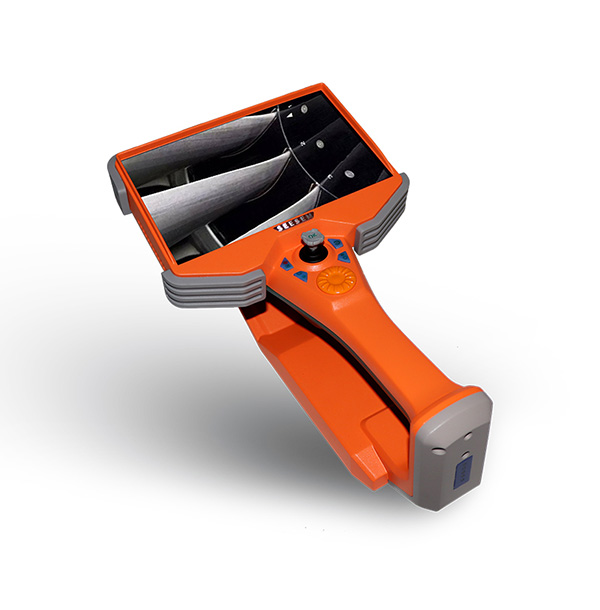

VJ-3 Video Borescope

The VJ-3 mechanical articulating video borescope is a nondestructive visual testing instrument used for the remote visual inspection of machinery, equipment, and components. The VJ-3 facilitates the visual recording and photo documentation of an inspection and components in areas that are otherwise inaccessible or require great effort and expense to access directly. The VJ-3 consists of two modules integrated into one system: an insertion tube with distally mounted camera/LEDs, and the base unit with control panel, LCD monitor, power source and all necessary circuitry.

ViewTech Borescopes, founded as RF System Lab in 2008, is North America’s #1 seller of video borescopes. Their first product, the VJ borescope, set a new standard for portability, ergonomics, and ease-of-use, with its industry-first mechanical, joystick-controlled articulation.

Videoscope for Remote Visual Inspection

A new line of industrial videoscopes from Titan Tool Supply, Inc. features one megapixel (1,000,000 pixels) resolution and offers six models in three viewing styles: front view, side view and dual front-side view. The new TVSH-35 HD Series video borescopes are designed for on-site inspections or maintenance and repair on a wide range of transportation equipment, including aviation, locomotive and gas and diesel engines; machinery, manufacturing and metalworking, including inspections of castings and cavities; pipeline and container manufacturing; as well as power generation, the company stated.To get more news about video borescope, you can visit seesemborescopes.com official website.

They feature a mechanized joystick that uses input to control the camera articulation and provide smooth, accurate control of the four-way articulating tip, with immediate response to the joystick inputs. This allows the camera tip to be steered through narrow bores, channels and complex curves.

Diameters are available in 3.8 mm and 6 mm in lengths of 1.5 m (59"), 3 m (118") and 5 m (197") for each. The probe length is 15 mm, and the bending angle is >/= 190° for all models. The new TVSH-35 HD videoscopes feature a 3.5" monitor with an image resolution of 1,280 x 720 pixels. Field of view is 120° and depth of view is 10 mm to 80 mm. A durable protective case has precision-cut inserts for safe carrying and storage.

Diameters are available in 3.8 mm and 6 mm in lengths of 1.5 m (59"), 3 m (118") and 5 m (197") for each. The probe length is 15 mm, and the bending angle is >/= 190° for all models. The new TVSH-35 HD videoscopes feature a 3.5" monitor with an image resolution of 1,280 x 720 pixels. Field of view is 120° and depth of view is 10 mm to 80 mm. A durable protective case has precision-cut inserts for safe carrying and storage.

Diameters are available in 3.8 mm and 6 mm in lengths of 1.5 m (59"), 3 m (118") and 5 m (197") for each. The probe length is 15 mm, and the bending angle is >/= 190° for all models. The new TVSH-35 HD videoscopes feature a 3.5" monitor with an image resolution of 1,280 x 720 pixels. Field of view is 120° and depth of view is 10 mm to 80 mm. A durable protective case has precision-cut inserts for safe carrying and storage.

Diameters are available in 3.8 mm and 6 mm in lengths of 1.5 m (59"), 3 m (118") and 5 m (197") for each. The probe length is 15 mm, and the bending angle is >/= 190° for all models. The new TVSH-35 HD videoscopes feature a 3.5" monitor with an image resolution of 1,280 x 720 pixels. Field of view is 120° and depth of view is 10 mm to 80 mm. A durable protective case has precision-cut inserts for safe carrying and storage. Titan Tool Supply Introduces Industrial Videoscope Series

a worldwide supplier of industrial-grade optical instrumentation and precision micro finishing tools, today announced the global market introduction of its TVM Series, a family of accurate, cost-effective, handheld industrial videoscopes.To get more news about industrial videoscope, you can visit seesemborescopes.com official website.

Offered in four standard models, TVM Series industrial videoscopes provide high-quality, speedy remote visual inspection and diagnostic capabilities across a diverse array of applications. All TVM Series models feature a 4.3-inch monitor and user-friendly button technology. Individual models are further offered with a choice of either a 4.5 mm or 6.2 mm diameter cable, and either a 1.5 m or 3 m working cable length. All TVM Series cabling further includes a Tungsten braided sleeving for added durability and reliability within dirty or harsh industrial applications.

The mechanical joystick that is incorporated into each Model TVM Series unit is expressly designed for ease of operator control. It offers full-360° four-way articulation, as well as operator-applied and guided input capabilities, for smooth, accurate, and direct control of both the camera and articulating camera tip during remote visual inspections. The camera can also accurately hold its designated position after joystick pressure is released. Design of the articulating camera tip incorporates a series of high-intensity LEDs with five-step intensity control. The LEDs allow the joystick to guide the videoscope more accurately and easily through narrow bores, channels, curves, and other complex geometries, and including in areas where diminished lighting conditions may otherwise be of concern.

Typical applications for the TVM Series include aviation MRO, automotive service inspections, casting inspections, cavity inspections, diesel and gasoline engine repair, locomotive maintenance, ship maintenance, industrial machinery and equipment monitoring, manufacturing quality control, or virtually any other industrial application requiring accurate, cost-effective remote visual inspection.

Since 1952, Titan Tool Supply has supported more than 5,700 customers in over 50 countries with its industrial-grade optical instrumentation offerings, including within the automotive, aerospace, commercial aviation, casting and parts manufacturing, gas and diesel engine, in-laboratory R&D, manufacturing quality assurance, oil and gas pipeline, shipping container, power generation, and industrial machinery and equipment industries. Some of the company’s most popular standard product lines include rigid and flexible industrial borescopes; industrial videoscopes; tool scopes; alignment telescopes; and centering, toolmaker, stereo, and monocular zoom microscopes. Approximately 85% of the company’s standard product portfolio is also fully video adaptable. In addition, Titan Tool Supply offers a series of its own high-precision video lens systems, specially designed for enhanced resolution and visualization capabilities.

Typical applications for the TVM Series include aviation MRO, automotive service inspections, casting inspections, cavity inspections, diesel and gasoline engine repair, locomotive maintenance, ship maintenance, industrial machinery and equipment monitoring, manufacturing quality control, or virtually any other industrial application requiring accurate, cost-effective remote visual inspection.

Since 1952, Titan Tool Supply has supported more than 5,700 customers in over 50 countries with its industrial-grade optical instrumentation offerings, including within the automotive, aerospace, commercial aviation, casting and parts manufacturing, gas and diesel engine, in-laboratory R&D, manufacturing quality assurance, oil and gas pipeline, shipping container, power generation, and industrial machinery and equipment industries. Some of the company’s most popular standard product lines include rigid and flexible industrial borescopes; industrial videoscopes; tool scopes; alignment telescopes; and centering, toolmaker, stereo, and monocular zoom microscopes. Approximately 85% of the company’s standard product portfolio is also fully video adaptable. In addition, Titan Tool Supply offers a series of its own high-precision video lens systems, specially designed for enhanced resolution and visualization capabilities.

Typical applications for the TVM Series include aviation MRO, automotive service inspections, casting inspections, cavity inspections, diesel and gasoline engine repair, locomotive maintenance, ship maintenance, industrial machinery and equipment monitoring, manufacturing quality control, or virtually any other industrial application requiring accurate, cost-effective remote visual inspection.

Since 1952, Titan Tool Supply has supported more than 5,700 customers in over 50 countries with its industrial-grade optical instrumentation offerings, including within the automotive, aerospace, commercial aviation, casting and parts manufacturing, gas and diesel engine, in-laboratory R&D, manufacturing quality assurance, oil and gas pipeline, shipping container, power generation, and industrial machinery and equipment industries. Some of the company’s most popular standard product lines include rigid and flexible industrial borescopes; industrial videoscopes; tool scopes; alignment telescopes; and centering, toolmaker, stereo, and monocular zoom microscopes. Approximately 85% of the company’s standard product portfolio is also fully video adaptable. In addition, Titan Tool Supply offers a series of its own high-precision video lens systems, specially designed for enhanced resolution and visualization capabilities.

Typical applications for the TVM Series include aviation MRO, automotive service inspections, casting inspections, cavity inspections, diesel and gasoline engine repair, locomotive maintenance, ship maintenance, industrial machinery and equipment monitoring, manufacturing quality control, or virtually any other industrial application requiring accurate, cost-effective remote visual inspection.

Since 1952, Titan Tool Supply has supported more than 5,700 customers in over 50 countries with its industrial-grade optical instrumentation offerings, including within the automotive, aerospace, commercial aviation, casting and parts manufacturing, gas and diesel engine, in-laboratory R&D, manufacturing quality assurance, oil and gas pipeline, shipping container, power generation, and industrial machinery and equipment industries. Some of the company’s most popular standard product lines include rigid and flexible industrial borescopes; industrial videoscopes; tool scopes; alignment telescopes; and centering, toolmaker, stereo, and monocular zoom microscopes. Approximately 85% of the company’s standard product portfolio is also fully video adaptable. In addition, Titan Tool Supply offers a series of its own high-precision video lens systems, specially designed for enhanced resolution and visualization capabilities.

Industrial videoscope being touted as the new ‘gold standard’

Catastrophic failure of machinery or structures is usually expensive to repair and can pose a threat to the health and safety of workers and the public.To get more news about video borescope, you can visit seesemborescopes.com official website.

Remote Visual Inspection (RVI) of materials, components and structures can give inspectors and technicians warnings of many potential failures before they cause problems.

A videoscope is an inspection instrument that consists of a small camera mounted on a length of cable that permits inspection of internal surfaces and other features of an engine, machinery or structure without causing damage to delicate parts or the need to dismantle.

Olympus—a leading manufacturer of optical, electronic and precision engineering products has been at the forefront of videoscope development for many decades and with the introduction of the iPlex NX industrial videoscope, the company enters a new era of precision with a unit that has the greatest measurement accuracy on the market allowing the detection of the smallest defects.

“The NX can be used for a broad range of applications and is the new ‘gold standard’ for videoscopes,” said Brendan Slaven, Product Specialist – RVI at Olympus. “This latest unit gives you the best of everything.” An iPlex NX can help locate flaws that were previously undetectable, as well as streamline inspections in even the most difficult-to-reach areas.

The scope combines an industry-leading high-pixel CCD chip, an ultra-bright laser diode light system delivered through the tip of the probe, and Olympus’ unique PulsarPic processor to automatically adjust light output, to deliver the clearest images possible in changeable inspection conditions.

According to Slaven, the iPlex NX has the highest resolution of any scope on the market. “The new design and other enhancements mean that the NX can accurately measure areas up to four times larger than conventional scopes,” he said.

The iPlex NX also offers a unique multi Spot-Ranging function that enables real-time measurement of the distance from the scope tip to multiple points on the inspection surface. This provides real-time surface shape information with no pause or break in the inspection. The videoscope camera can be controlled remotely by an operator while it is inserted in the cavity to be inspected.

Olympus’ pioneering TrueFeel electric articulation has been enhanced with reduced mechanical lag and greater sensitivity giving the NX ultra-responsive articulation and an increased range of motion in four directions.

“The NX is also the first high-end scope with a touch screen interface,” Slaven added. “You have the choice between the touch screen or Olympus’s ergonomically designed manual controls to suit the environment and inspection application.”

The touch screen is manoeuvrable for optimised ergonomics and viewing comfort allowing for more than a dozen commonly used functions to be changed with a single touch. The NX videoscope can be configured for a variety of inspection tasks, with 6.0 mm probes ranging in length from 3.5m to 7.5m and 4.0mm probes with lengths of 3.5m and 5m.

The finer probe tip allows access to very confined spaces such as between heat exchanger tubes or turbine blades. The compact and robust construction of the NX design has achieved International Protection Rating of IP55 and complies with stringent US military standards for dust and rain resistance, as well as drop testing.

The 8.4-inch display screen has an anti-reflective daylight-view monitor, allowing accurate inspections even in direct sunlight. The smaller size makes the iPlex NX ideal for locations with limited operator access including boilers, aeroplane fuselages and engines, and wind turbine gearboxes.

Post-inspection tasks such as archiving and reporting are simplified as operators can quickly recall and give titles to captured images from the NX display console. Olympus’ optional InHelp data management and reporting software automatically saves images in folders organised by inspection location.

Diagnostic information can easily be added to specific images using a couple of button clicks during the inspection, which saves valuable time back in the office. If changes need to be made or results queried, images and video data—including measurements, comments and other annotations—can be edited at any stage on a PC for reporting purposes.

A videoscope is an inspection instrument that consists of a small camera mounted on a length of cable that permits inspection of internal surfaces and other features of an engine, machinery or structure without causing damage to delicate parts or the need to dismantle.

Olympus—a leading manufacturer of optical, electronic and precision engineering products has been at the forefront of videoscope development for many decades and with the introduction of the iPlex NX industrial videoscope, the company enters a new era of precision with a unit that has the greatest measurement accuracy on the market allowing the detection of the smallest defects.

“The NX can be used for a broad range of applications and is the new ‘gold standard’ for videoscopes,” said Brendan Slaven, Product Specialist – RVI at Olympus. “This latest unit gives you the best of everything.” An iPlex NX can help locate flaws that were previously undetectable, as well as streamline inspections in even the most difficult-to-reach areas.

The scope combines an industry-leading high-pixel CCD chip, an ultra-bright laser diode light system delivered through the tip of the probe, and Olympus’ unique PulsarPic processor to automatically adjust light output, to deliver the clearest images possible in changeable inspection conditions.

According to Slaven, the iPlex NX has the highest resolution of any scope on the market. “The new design and other enhancements mean that the NX can accurately measure areas up to four times larger than conventional scopes,” he said.

The iPlex NX also offers a unique multi Spot-Ranging function that enables real-time measurement of the distance from the scope tip to multiple points on the inspection surface. This provides real-time surface shape information with no pause or break in the inspection. The videoscope camera can be controlled remotely by an operator while it is inserted in the cavity to be inspected.

Olympus’ pioneering TrueFeel electric articulation has been enhanced with reduced mechanical lag and greater sensitivity giving the NX ultra-responsive articulation and an increased range of motion in four directions.

“The NX is also the first high-end scope with a touch screen interface,” Slaven added. “You have the choice between the touch screen or Olympus’s ergonomically designed manual controls to suit the environment and inspection application.”

The touch screen is manoeuvrable for optimised ergonomics and viewing comfort allowing for more than a dozen commonly used functions to be changed with a single touch. The NX videoscope can be configured for a variety of inspection tasks, with 6.0 mm probes ranging in length from 3.5m to 7.5m and 4.0mm probes with lengths of 3.5m and 5m.

The finer probe tip allows access to very confined spaces such as between heat exchanger tubes or turbine blades. The compact and robust construction of the NX design has achieved International Protection Rating of IP55 and complies with stringent US military standards for dust and rain resistance, as well as drop testing.

The 8.4-inch display screen has an anti-reflective daylight-view monitor, allowing accurate inspections even in direct sunlight. The smaller size makes the iPlex NX ideal for locations with limited operator access including boilers, aeroplane fuselages and engines, and wind turbine gearboxes.

Post-inspection tasks such as archiving and reporting are simplified as operators can quickly recall and give titles to captured images from the NX display console. Olympus’ optional InHelp data management and reporting software automatically saves images in folders organised by inspection location.

Diagnostic information can easily be added to specific images using a couple of button clicks during the inspection, which saves valuable time back in the office. If changes need to be made or results queried, images and video data—including measurements, comments and other annotations—can be edited at any stage on a PC for reporting purposes.

A videoscope is an inspection instrument that consists of a small camera mounted on a length of cable that permits inspection of internal surfaces and other features of an engine, machinery or structure without causing damage to delicate parts or the need to dismantle.

Olympus—a leading manufacturer of optical, electronic and precision engineering products has been at the forefront of videoscope development for many decades and with the introduction of the iPlex NX industrial videoscope, the company enters a new era of precision with a unit that has the greatest measurement accuracy on the market allowing the detection of the smallest defects.

“The NX can be used for a broad range of applications and is the new ‘gold standard’ for videoscopes,” said Brendan Slaven, Product Specialist – RVI at Olympus. “This latest unit gives you the best of everything.” An iPlex NX can help locate flaws that were previously undetectable, as well as streamline inspections in even the most difficult-to-reach areas.

The scope combines an industry-leading high-pixel CCD chip, an ultra-bright laser diode light system delivered through the tip of the probe, and Olympus’ unique PulsarPic processor to automatically adjust light output, to deliver the clearest images possible in changeable inspection conditions.

According to Slaven, the iPlex NX has the highest resolution of any scope on the market. “The new design and other enhancements mean that the NX can accurately measure areas up to four times larger than conventional scopes,” he said.

The iPlex NX also offers a unique multi Spot-Ranging function that enables real-time measurement of the distance from the scope tip to multiple points on the inspection surface. This provides real-time surface shape information with no pause or break in the inspection. The videoscope camera can be controlled remotely by an operator while it is inserted in the cavity to be inspected.

Olympus’ pioneering TrueFeel electric articulation has been enhanced with reduced mechanical lag and greater sensitivity giving the NX ultra-responsive articulation and an increased range of motion in four directions.

“The NX is also the first high-end scope with a touch screen interface,” Slaven added. “You have the choice between the touch screen or Olympus’s ergonomically designed manual controls to suit the environment and inspection application.”

The touch screen is manoeuvrable for optimised ergonomics and viewing comfort allowing for more than a dozen commonly used functions to be changed with a single touch. The NX videoscope can be configured for a variety of inspection tasks, with 6.0 mm probes ranging in length from 3.5m to 7.5m and 4.0mm probes with lengths of 3.5m and 5m.

The finer probe tip allows access to very confined spaces such as between heat exchanger tubes or turbine blades. The compact and robust construction of the NX design has achieved International Protection Rating of IP55 and complies with stringent US military standards for dust and rain resistance, as well as drop testing.

The 8.4-inch display screen has an anti-reflective daylight-view monitor, allowing accurate inspections even in direct sunlight. The smaller size makes the iPlex NX ideal for locations with limited operator access including boilers, aeroplane fuselages and engines, and wind turbine gearboxes.

Post-inspection tasks such as archiving and reporting are simplified as operators can quickly recall and give titles to captured images from the NX display console. Olympus’ optional InHelp data management and reporting software automatically saves images in folders organised by inspection location.

Diagnostic information can easily be added to specific images using a couple of button clicks during the inspection, which saves valuable time back in the office. If changes need to be made or results queried, images and video data—including measurements, comments and other annotations—can be edited at any stage on a PC for reporting purposes.

A videoscope is an inspection instrument that consists of a small camera mounted on a length of cable that permits inspection of internal surfaces and other features of an engine, machinery or structure without causing damage to delicate parts or the need to dismantle.

Olympus—a leading manufacturer of optical, electronic and precision engineering products has been at the forefront of videoscope development for many decades and with the introduction of the iPlex NX industrial videoscope, the company enters a new era of precision with a unit that has the greatest measurement accuracy on the market allowing the detection of the smallest defects.

“The NX can be used for a broad range of applications and is the new ‘gold standard’ for videoscopes,” said Brendan Slaven, Product Specialist – RVI at Olympus. “This latest unit gives you the best of everything.” An iPlex NX can help locate flaws that were previously undetectable, as well as streamline inspections in even the most difficult-to-reach areas.

The scope combines an industry-leading high-pixel CCD chip, an ultra-bright laser diode light system delivered through the tip of the probe, and Olympus’ unique PulsarPic processor to automatically adjust light output, to deliver the clearest images possible in changeable inspection conditions.

According to Slaven, the iPlex NX has the highest resolution of any scope on the market. “The new design and other enhancements mean that the NX can accurately measure areas up to four times larger than conventional scopes,” he said.

The iPlex NX also offers a unique multi Spot-Ranging function that enables real-time measurement of the distance from the scope tip to multiple points on the inspection surface. This provides real-time surface shape information with no pause or break in the inspection. The videoscope camera can be controlled remotely by an operator while it is inserted in the cavity to be inspected.

Olympus’ pioneering TrueFeel electric articulation has been enhanced with reduced mechanical lag and greater sensitivity giving the NX ultra-responsive articulation and an increased range of motion in four directions.

“The NX is also the first high-end scope with a touch screen interface,” Slaven added. “You have the choice between the touch screen or Olympus’s ergonomically designed manual controls to suit the environment and inspection application.”

The touch screen is manoeuvrable for optimised ergonomics and viewing comfort allowing for more than a dozen commonly used functions to be changed with a single touch. The NX videoscope can be configured for a variety of inspection tasks, with 6.0 mm probes ranging in length from 3.5m to 7.5m and 4.0mm probes with lengths of 3.5m and 5m.

The finer probe tip allows access to very confined spaces such as between heat exchanger tubes or turbine blades. The compact and robust construction of the NX design has achieved International Protection Rating of IP55 and complies with stringent US military standards for dust and rain resistance, as well as drop testing.

The 8.4-inch display screen has an anti-reflective daylight-view monitor, allowing accurate inspections even in direct sunlight. The smaller size makes the iPlex NX ideal for locations with limited operator access including boilers, aeroplane fuselages and engines, and wind turbine gearboxes.

Post-inspection tasks such as archiving and reporting are simplified as operators can quickly recall and give titles to captured images from the NX display console. Olympus’ optional InHelp data management and reporting software automatically saves images in folders organised by inspection location.

Diagnostic information can easily be added to specific images using a couple of button clicks during the inspection, which saves valuable time back in the office. If changes need to be made or results queried, images and video data—including measurements, comments and other annotations—can be edited at any stage on a PC for reporting purposes.